100% Made in Italy clothing

Ethical production has been one of our core values from the beginning and being able to support our local community and the small artisan factories in our area is one of our greatest satisfactions. Italy is a country full of passion and love and we wanted to be able to transmit this energy through our products.

Ethical production at 70 km

A community based on friendship and respect

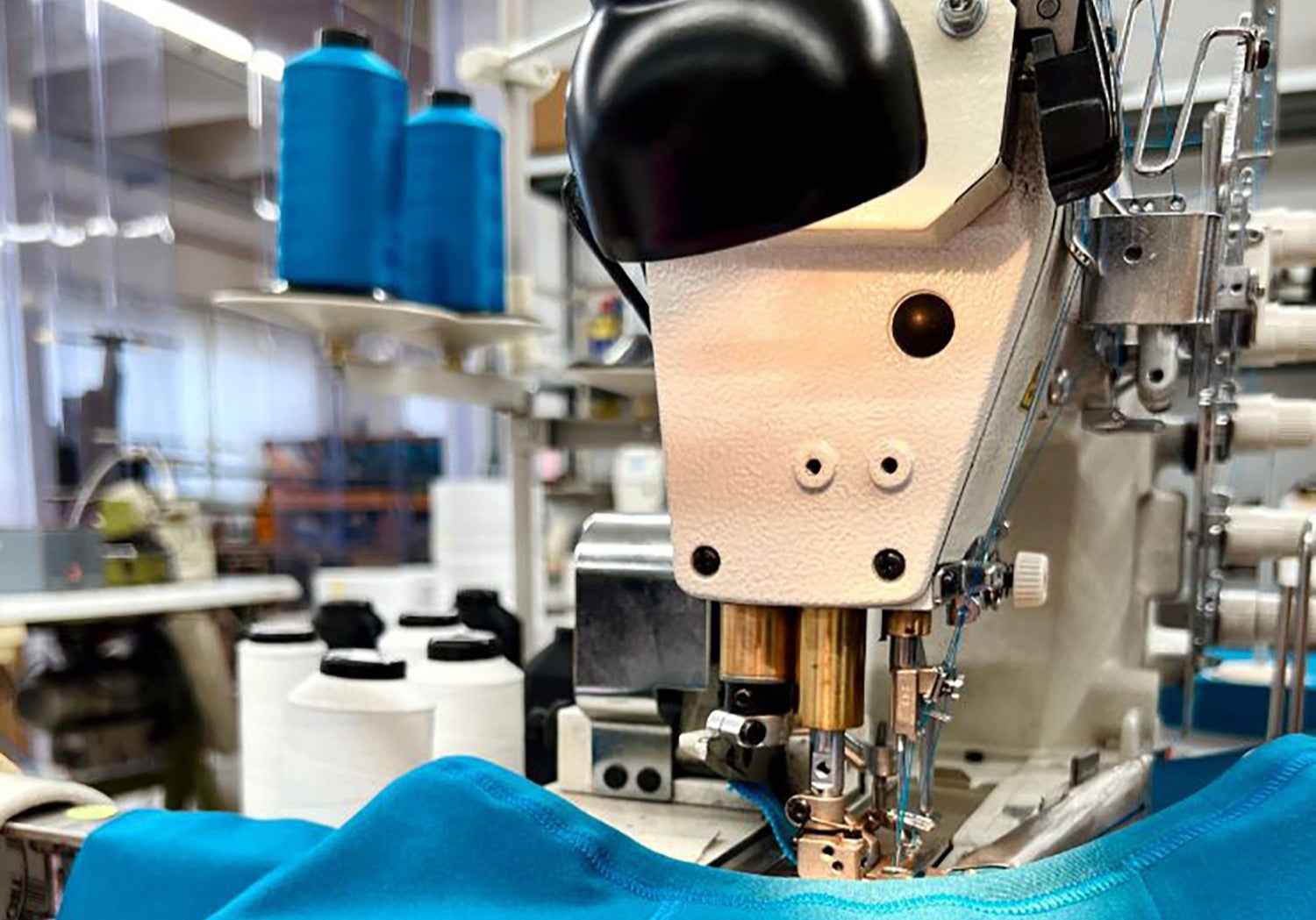

Every part of our production process takes place within a 70 km radius of our headquarters in Padua in small, often family-run businesses, where the work of each individual is valued and where craftsmanship is still considered art. We are always in close contact with our community and we love working with people who have the same passion and creative spirit as us: it never gets boring!

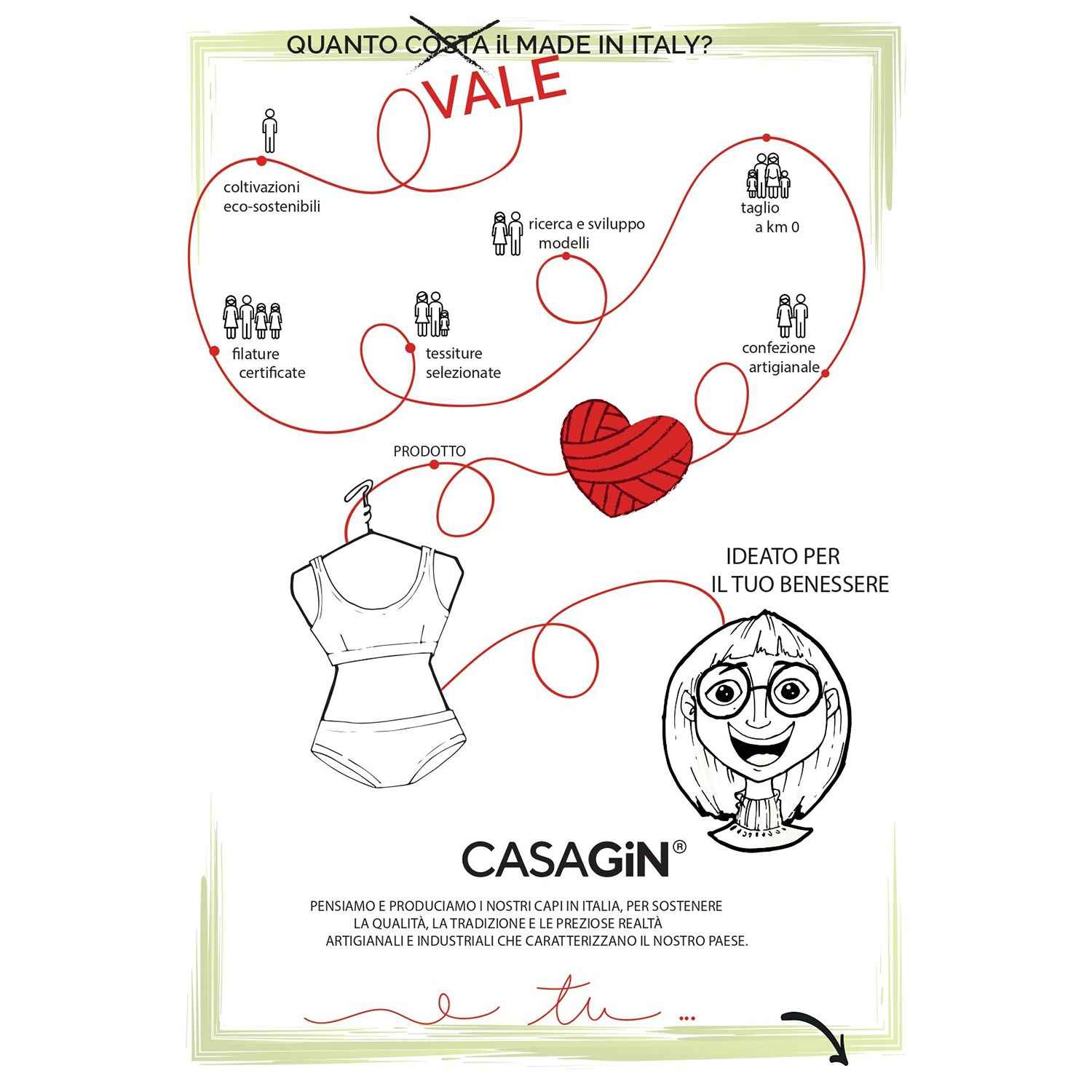

Our Made in Italy includes the entire value chain, from the yarn to the final product

It is difficult to realize how many steps and how many people are involved in the creation of a single piece of clothing. From processing the yarns to dyeing, from preparing the patterns to cutting the fabrics: the assembly and packaging of the garment is only a final phase of an integrated flow of creation.

Italian certifications, safety and quality

In addition to ethical aspects, there is another reason why we have chosen to produce exclusively in Italy: it is a question of safety! With everything we do we want to create a feeling of well-being for everyone involved, from workers to our customers. Therefore, creating products that do not cause harm to human health, safety and the environment is our number one priority and choosing only certified local businesses is the only way to guarantee the highest production standards. Our fabrics are subjected to the most severe safety standards that only Italian production can guarantee, including the STANDARD 100 by OEKO-TEX® which certifies the harmlessness to human health and the environment of the dyes used.

A sustainable choice

We wanted to find and create a network of people who share our same values in each production area. Passion for Italian craftsmanship is what brought us together, but love for the environment is what keeps us together. Every member of our value chain is committed to sustainable business practices and reducing their environmental impact

For example, the company that packages most of our products is self-sufficient in terms of energy thanks to the use of photovoltaic panels. But even downstream in the supply chain, we always choose suppliers who implement sustainable processes. The suppliers of our main fabrics are committed to reducing CO2 throughout the entire production process and have developed a closed system to recover and recycle the water used. The energy used in the factories also comes 100% from renewable sources and many have installed a system to save and reuse the energy used in the various processes. Another important criterion for CASAGiN is waste reduction. In fact, all fabric suppliers are committed to recycling their production waste.

Transparency

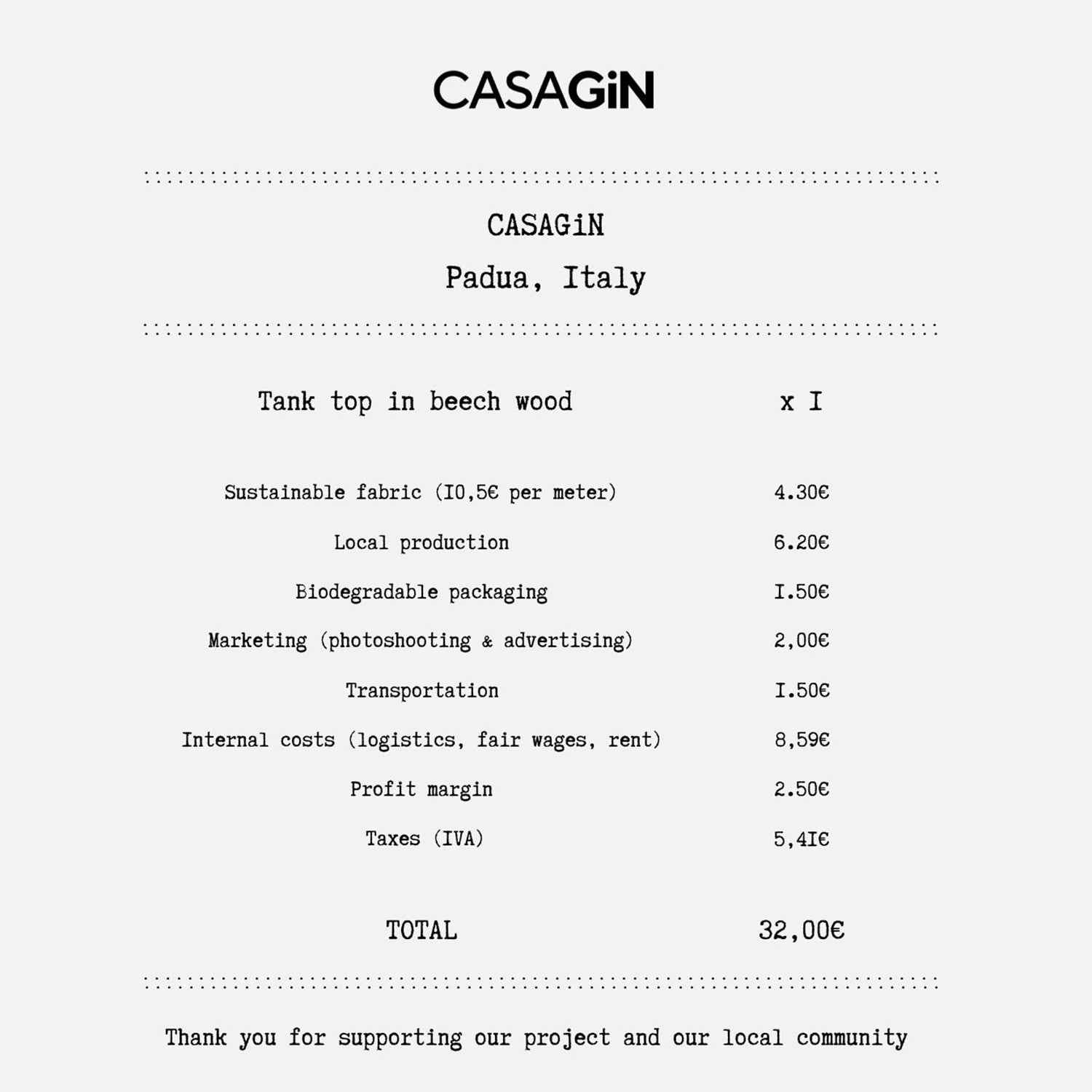

We wanted to make you understand what our price includes, which is also fair when compared to other brands. When you read the price of a product you have to think about the cost of the raw material and all the people who put their KNOW-HOW into making something unique with their own hands; it is important to reflect on the fact that they must be paid decently for their work.

Visit our laboratories

Lenzing, Austria

TENCEL™ is the registered trademark with which this Austrian company, the only one in the world to guarantee the sustainability cycle of the manufacturing process, marks the special fibers we use, obtained from eucalyptus wood (TENCEL™ Lyocell) and beech wood (TENCEL™ Modal). The production of these fibers is extremely ecological, thanks to a patented closed-circuit manufacturing system, which starts from nature to return to it in an absolutely eco-compatible form.

Year of foundation = 1982

Family run = No

Number of employees = 6000

Guarantees adopted for employees = Global Code of Business Conduct

Internal processes = Fiber production

Products made = Underwear and clothing in TENCEL™ Lyocell and TENCEL™ Modal

Certifications = European Ecolabel, USDA Certified Biobased Product, TUV AUSTRIA BELGIUM NV, Oeko-Tex Standard 100, FSC, PEFC, Responsible Care, Fairtrade, Standard ISO, Medically Tested, ISEGA, RCS

Environmental policies = Environmental policies Energy efficiency, water recycling systems, air quality, improved management of natural resources, waste reduction, responsible management of chemicals

Trento, Italy

For more than 50 years, this company has been one of the main players, in Italy and in the world, in the production of ecological fibers. The Group is a point of reference for quality, innovation and new models of sustainable development. A strategic choice that is realized through ECONYL®, a nylon fiber obtained by transforming waste such as fishing nets that can no longer be used and textile production scraps, into a new source of opportunities.

Year of foundation = 1969

Family run = No

Number of employees = 2700

Guarantees adopted for employees = National collective labor agreement

Internal processes = Fiber production

Products made = ECONYL® Swimwear

Certifications = ISO Standard, REACH, Oeko-Tex Standard 100, EPD, GRS

Environmental policies = Energy efficiency, water recycling systems, air quality, improved management of natural resources, waste reduction, responsible management of chemicals

Bergamo, Italy

This company has been producing warp-knit and circular-knit fabrics for high performance for over fifty years. Materials that represent, in the world, the excellence of the Italian textile sector. Experience and advanced technologies to provide a wide range of technical fabrics designed and tested to meet the numerous needs that increasingly attentive consumers require.

Year of foundation = 1962

Family run = Yes

Number of employees = 350

Guarantees adopted for employees = National collective labor agreement

Internal processes = Weaving dyeing

Products made = ECONYL® Swimwear

Certifications = REACH, ISO Standard, Oeko-Tex Standard 100

Environmental policies = Energy efficiency, water recycling systems, air quality, improved management of natural resources, waste reduction, responsible management of chemicals

Varese, Italy

A company that for several decades has faced the challenges of the textile sector by continually renewing itself and by adding lines more suited to the new needs that the international market requires to the traditional clothing sectors. A guarantee of high quality and reliability that combines the search for the most innovative raw materials on the market with the use of certified yarns and the most advanced dyeing and finishing techniques.

Year of foundation = 1970

Family run = Yes

Number of employees = 27

Guarantees adopted for employees = National collective labor agreement

Internal processes = Weaving Dyeing

Products made = GOTS organic cotton T-shirts

Certifications = GOTS, GRS, ZDHC, Oeko-Tex Standard 100

Environmental Policies = Responsible Management of Chemicals

Brescia, Italy

A company that has grown following the fundamental principles of quality and service, which has constantly increased the wide range of yarns offered in various types and colors, qualitatively tested throughout the production chain. A team qualified for stylistic, technical and commercial aspects is constantly engaged in the search for strategic guidelines for each collection, so as to anticipate new market trends and satisfy any request.

Year of foundation = 1993

Family run = No

Number of employees = 32

Guarantees adopted for employees = National collective labor agreement, Code of ethics

Internal processes = Spinning

Products made = Socks in TENCEL™ Lyocell, GOTS organic cotton, recycled PET

Certifications = GRS, RCS, GOTS, Oeko-Tex Standard 100, ZHDC, Detox

Environmental policies = Energy efficiency, water recycling systems, improved management of natural resources, waste reduction, responsible management of chemicals

Venice, Italy

Located a stone's throw from Venice, this company has grown and modernized in full respect of the environment, while maintaining its family-run characteristics. The entire production cycle of the garments produced is completed within the company: from the study of the model to its creation, from the selection of strictly Italian raw materials, to the final packaging and quality control.

Year of foundation = 1982

Family run = Yes

Number of employees = 14

Guarantees adopted for employees = National collective labor agreement

Internal processes = Packaging

Products made = Underwear and clothing in TENCEL™ Modal

Certifications = 100% Made in Italy

Environmental policies = Energy efficiency, improved management of natural resources, waste reduction, responsible management of chemicals

Rovigo, Italy

A small artisan workshop that aims to research the details and find the best way to package the garments, making the most of many years of experience in this sector. Today this group of experts stands out for its ability to identify the best cutting and sewing techniques so as to perfectly create every commissioned garment. Passion and dedication make this reality a point of reference in Made in Italy.

Year of foundation = 1984

Family run = Yes

Number of employees = 12

Guarantees adopted for employees = National collective labor agreement

Internal processes = Packaging

Products made = ECONYL® Swimwear

Environmental policies = Improved management of natural resources, waste reduction

Urgnano, Italy

A leading company in the production of warp-knitted elastic fabrics with the recognized ability to stimulate the creative spirit and transform the ideas of its customers into concrete reality. A path in continuous evolution, supported by the stimuli that the founding family has never stopped giving. Thanks to continuous innovation it stands out on the market, being appreciated for the maximum attention dedicated to details and for guaranteeing performance and quality of service.

Year of foundation = 1931

Family run = No

Number of employees = 150

Guarantees adopted for employees = National collective labor agreement, Code of ethics, SA8000

Internal processes = Weaving, dyeing

Products made = Sportswear

Certifications = Bluesign, Oeko-Tex Standard 100, ISO Standard, SA8000

Environmental policies = Energy efficiency, water recycling systems, air quality, improved management of natural resources, waste reduction, responsible management of chemicals